This strategy emphasizes the necessity of a everyday living cycle method, which begins with process style and design and continues through process qualification and continued process verification.

Process validation is the Assessment of knowledge collected all over the style and design and manufacturing of an item to be able to verify that the process can reliably output goods of a established standard. Regulatory authorities like EMA and FDA have released guidelines regarding process validation.[1] The objective of process validation is to be sure diversified inputs bring about steady and high quality outputs.

The 2nd phase consists of demonstrating which the process is capable of continually generating items that fulfill the predetermined high quality characteristics. It involves the execution of validation protocols to validate the process efficiency and the collection of information to assist the validation.

Process validation allows pharmaceutical companies in order that every single move of the manufacturing process contributes to making helpful and Safe and sound prescription drugs. Adhering to all regulations and criteria is essential for sustaining dependable product or service high quality.

PQ is the ultimate step while in the process qualification stage and will involve verifying that the process constantly generates goods conforming to their predetermined specs.

It is completed throughout common pharmaceutical manufacturing to exhibit that the process performs at the level that it must in the middle of its precise execution. Though concurrent validation remains to be an acceptable approach to process validation less than specific circumstances (e.

The second phase involves demonstrating which the process is able to consistently generating products that meet the predetermined top quality characteristics. It incorporates the execution of validation protocols to verify the process functionality process validation ich guidelines and the collection of information to guidance the validation.

PQ is the ultimate stage inside the process qualification stage and consists of verifying the process consistently makes products conforming for their predetermined technical specs.

Discover what QSR management is, why it’s important, and how to put into action a QSR administration strategy as part of your operations properly.

History reveals that just Conference final product standards is not really ample. Gathering info through the entire creation process is important to make certain Risk-free, large-high-quality pharmaceuticals.

Risk evaluation performs a vital position in process validation. By identifying potential hazards and regions of worry, businesses can concentrate their validation endeavours on critical process parameters and steps.

Inside the hugely regulated and speedy-paced entire world of producing, excellent Regulate is of utmost significance. Corporations should be certain that their processes are trusted, dependable, and effective at constantly making products which fulfill the best specifications. This is when process validation arrives into Participate in.

ValGenesis' electronic process validation Alternative can help businesses conquer process validation get more info complexity from style to professional generation when developing scientific proof they could deliver a safe, substantial-high quality product.

I've been tasked with encouraging a client choose how to find out if incoming reused devices is "cleanse". After several hours of searching for applicable info your web site is The very first time I have gotten some authentic help. Thank you.

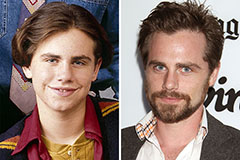

Jake Lloyd Then & Now!

Jake Lloyd Then & Now! Rider Strong Then & Now!

Rider Strong Then & Now! Marla Sokoloff Then & Now!

Marla Sokoloff Then & Now! Elin Nordegren Then & Now!

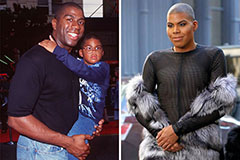

Elin Nordegren Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now!